Selecting the right PCB Fabrication Company is crucial for the success of your electronics project. The right partner will ensure high-quality production, timely delivery, and support throughout the process. In this comprehensive guide, we will walk you through the key considerations for choosing the best PCB fabrication company for your needs.

Understanding PCB Fabrication

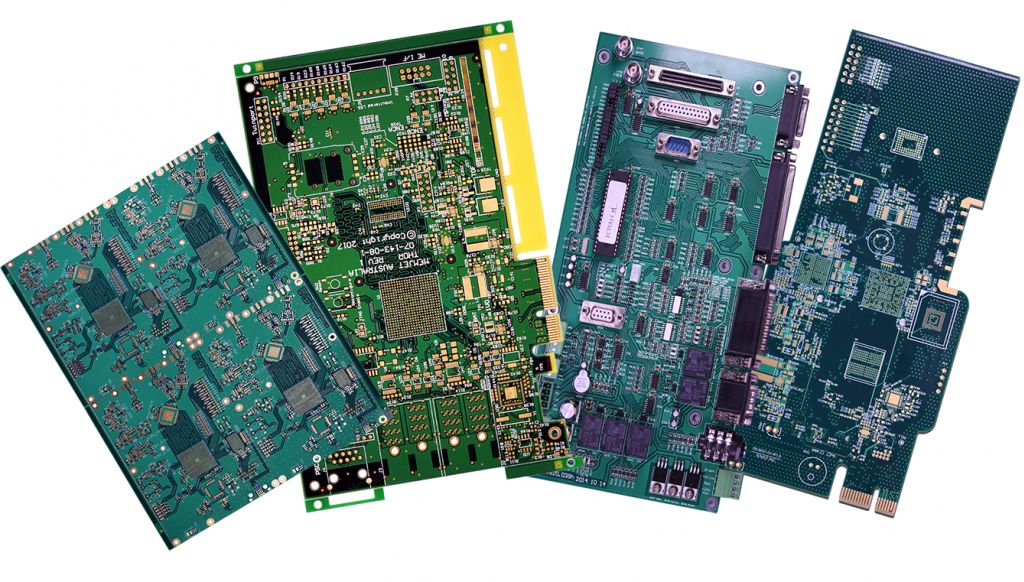

PCB (Printed Circuit Board) fabrication involves the process of manufacturing the physical boards that connect electronic components using conductive pathways. These pathways are etched from copper sheets laminated onto a non-conductive substrate.

Key Elements in PCB Fabrication

- PCB Board Design: The design phase is critical and involves creating a layout that defines the board’s electrical connections. Companies specializing in PCB board design, especially those in China, offer advanced design services to meet complex requirements.

- PCB Board Layers: PCBs can be single-layer, double-layer, or multi-layer. Multi-layer boards, with more than two layers, are essential for complex electronics, offering greater design flexibility and improved performance.

- Surface Mount Technology (SMT): Surface mount PCB boards utilize SMT to place components directly onto the surface of the board, allowing for smaller and more efficient designs.

- PCB Components Identification: Proper identification and placement of components are vital to ensure the functionality and reliability of the PCB.

Key Considerations for Choosing a PCB Fabrication Company

1. Quality Standards

High-quality PCBs are essential for the reliability and performance of your electronic products. Ensure that the PCB fabrication companies you consider adhere to international quality standards such as ISO 9001, IPC-A-600, and IPC-A-610. These certifications indicate that the company follows stringent quality control processes.

2. Manufacturing Capabilities

Evaluate the manufacturing capabilities of potential PCB fabrication companies. Consider the following factors:

- Layer Count: Ensure the company can produce the required number of PCB board layers.

- Material Options: Check if they offer a variety of materials suitable for your project’s needs.

- Advanced Technologies: Look for companies that utilize advanced manufacturing technologies such as SMT for surface mount PCB boards.

- Production Volume: Ensure the company can handle your required production volume, whether it’s a prototype, small batch, or mass production.

3. Design Support

Many projects require robust design support to ensure successful PCB fabrication. Look for companies that offer comprehensive design services, including PCB board design in China, where many leading manufacturers provide advanced design capabilities. A good design team can help optimize your design for manufacturing, reducing costs and improving quality.

4. Lead Times and Delivery

Timely delivery is crucial for meeting project deadlines. Inquire about the typical lead times for prototypes, small batches, and mass production orders. Additionally, consider the company’s ability to handle urgent orders and their shipping methods to ensure your PCBs arrive on time.

5. Cost and Pricing Structure

Cost is always a significant consideration. Obtain detailed quotes from multiple PCB fabrication companies to compare pricing structures. Ensure that the quotes include all costs, such as setup fees, material costs, and any additional charges for design support or expedited delivery. While cost is important, it should not be the sole deciding factor; quality and reliability are equally crucial.

6. Customer Support and Communication

Effective communication and strong customer support are essential for a smooth fabrication process. Choose a company that provides clear and prompt communication, technical support, and after-sales service. This is particularly important when dealing with overseas manufacturers, such as those involved in PCB board design in China.

7. Reputation and Reviews

Research the reputation of potential PCB fabrication companies. Look for customer reviews, testimonials, and case studies to gauge their reliability and performance. Additionally, consider seeking recommendations from industry peers who have experience with specific manufacturers.

Advantages of Choosing PCB Fabrication Companies in China

China is a global leader in PCB fabrication, known for its advanced manufacturing capabilities, competitive pricing, and extensive supply chain. Here are some advantages of working with PCB fabrication companies in China:

- Cost-Effective Production: Chinese manufacturers often offer lower production costs due to economies of scale and lower labor costs.

- Advanced Technology: Many PCB fabrication companies in China utilize state-of-the-art technology and equipment, ensuring high-quality production.

- Comprehensive Services: From PCB board design to multi-layer fabrication and surface mount technology, Chinese companies provide a wide range of services.

- Large-Scale Production: With their extensive manufacturing facilities, Chinese companies can handle large-scale production runs efficiently.

Steps to Ensure a Successful Partnership

1. Define Your Requirements

Clearly outline your project requirements, including design specifications, layer count, materials, and production volume. Providing detailed information will help the PCB fabrication companies understand your needs and provide accurate quotes.

2. Request Prototypes

Before committing to large-scale production, request prototypes from potential manufacturers. This allows you to evaluate the quality, accuracy, and performance of their work. It’s also an opportunity to identify any design adjustments needed before full production.

3. Evaluate Samples

Carefully evaluate the prototypes for any defects or inconsistencies. Ensure that the PCB components identification and placement are accurate, and the board functions as expected.

4. Establish Clear Communication

Maintain open and clear communication with the chosen PCB Fabrication Company. Regular updates and prompt responses to queries will help prevent misunderstandings and ensure the project progresses smoothly.

5. Monitor Production

Once production begins, monitor the process closely. Regular updates and progress reports from the manufacturer will help you stay informed and address any issues promptly.

Conclusion

Choosing the best PCB fabrication company for your project is a critical decision that can significantly impact the quality, cost, and timeline of your product development. By considering factors such as quality standards, manufacturing capabilities, design support, lead times, and customer service, you can find a reliable partner to meet your needs.

China’s leading role in electronics manufacturing, particularly in PCB board design and fabrication, offers numerous advantages. Leveraging these capabilities can provide you with high-quality, cost-effective solutions for your electronics projects.

Read More: How to Choose the Best PCB Fabrication Company for Your Project: A Comprehensive Guide | Viasion