Selecting the right PCB Fabrication Company is crucial for the success of your electronics project. Whether you’re developing a prototype or launching a full-scale production, partnering with a reliable and experienced PCB manufacturer is essential. This comprehensive guide delves into the factors you should consider when choosing a PCB fabrication company, highlighting key criteria, industry insights, and best practices to ensure you make an informed decision.

Understanding PCB Fabrication Companies

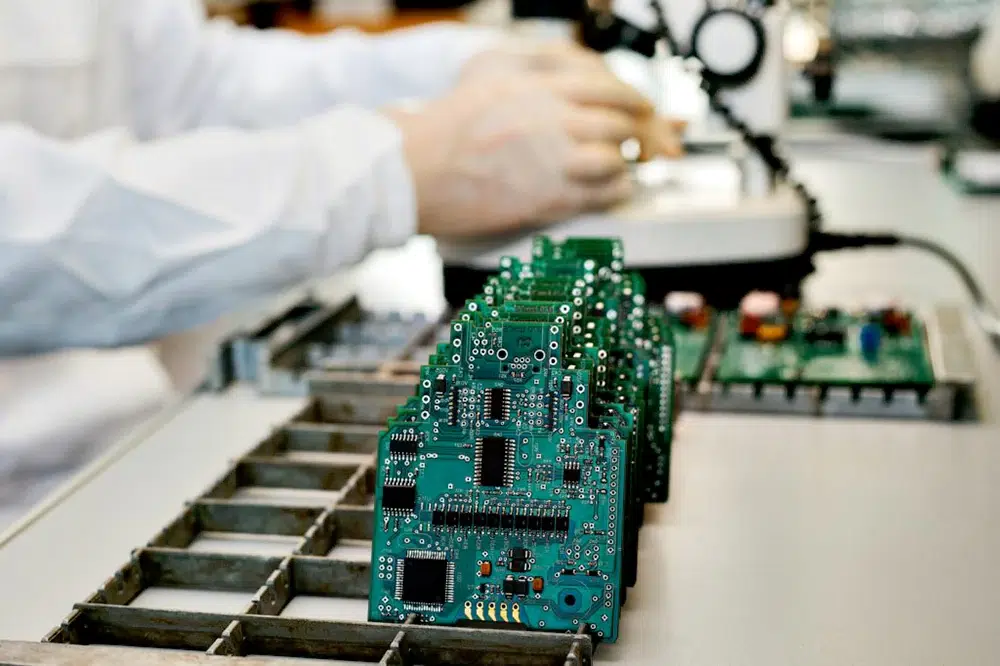

PCB fabrication companies specialize in manufacturing printed circuit boards (PCBs), which are essential components of electronic devices. These companies offer a range of services, from PCB design and layout to assembly and testing. Choosing the best PCB fabrication company involves evaluating its capabilities, quality standards, production capacity, and adherence to industry regulations.

Key Considerations for Choosing a PCB Fabrication Company

- Quality and Reliability

Ensure the PCB fabrication company adheres to stringent quality standards, such as ISO certifications and IPC standards. Quality assurance processes, including thorough testing and inspection procedures, are crucial to delivering reliable PCBs that meet your specifications.

- Capabilities and Services

Evaluate the company’s capabilities in PCB manufacturing, including PCB board design, layout services, and assembly options. Look for expertise in handling various PCB types (single-layer, double-layer, multi-layer) and advanced technologies like HDI (High-Density Interconnect) and flexible PCBs.

- Experience and Industry Reputation

Consider the company’s experience in the electronics production industry and its reputation among peers and customers. Reviews, testimonials, and case studies can provide insights into their track record of delivering quality PCBs and meeting project timelines.

- Technical Expertise and Support

Assess the company’s technical expertise and support capabilities. A knowledgeable team of engineers and support staff can assist in PCB design optimization, component selection, and resolving technical challenges throughout the manufacturing process.

- Production Capacity and Lead Times

Evaluate the company’s production capacity and lead times to ensure they can accommodate your project requirements. Factors such as batch sizes, turnaround times, and flexibility in scheduling are critical for meeting production deadlines and scaling production as needed.

- Cost-Effectiveness and Pricing Transparency

Compare pricing structures among PCB fabrication companies, considering factors like setup fees, tooling costs, and volume discounts. Transparency in pricing and clear communication regarding additional charges can help you budget effectively and avoid unexpected costs.

Industry Insights and Trends in PCB Fabrication

- Advancements in PCB Technology

The evolution of PCB technology, including miniaturization, increased component density, and integration of advanced materials, drives innovation in electronic device manufacturing. Look for a PCB fabrication company that stays updated with these technological advancements.

- Emerging Markets and Global Supply Chain Dynamics

PCB Fabrication Companies with global supply chain networks can offer competitive advantages in sourcing materials, components, and manufacturing capabilities. Consider geographical advantages, such as proximity to electronics manufacturing hubs like China.

- Environmental Sustainability

Sustainable practices in PCB manufacturing, such as eco-friendly materials and energy-efficient processes, are becoming increasingly important. Choose a PCB fabrication company committed to environmental responsibility and compliance with regulatory standards.

Best Practices for Selecting a PCB Fabrication Company

- Define Your Requirements: Clearly outline your project requirements, including PCB specifications, quantity, budget, and timeline.

- Request Multiple Quotes: Obtain quotes from several PCB fabrication companies to compare services, pricing, and terms.

- Review Samples and Prototypes: Request samples or prototypes to evaluate the company’s manufacturing quality and capabilities firsthand.

- Visit Facilities (if possible): If feasible, visit the PCB fabrication company’s facilities to assess their equipment, processes, and overall operations.

- Check Customer Support and Communication: Evaluate the responsiveness and support provided by the company’s customer service team. Effective communication is crucial for successful project management.

Conclusion

Choosing the best PCB fabrication company requires careful consideration of various factors, from quality and reliability to technical expertise and production capabilities. By following this comprehensive guide and leveraging industry insights, you can confidently select a PCB fabrication partner that meets your project needs and contributes to the success of your electronic device manufacturing endeavours.

At Viasion, we specialize in providing top-tier PCB fabrication services tailored to meet the diverse needs of our clients. Whether you’re seeking PCB board design services, PCB layout optimization, or comprehensive electronic device manufacturing solutions, our team is here to support your journey from concept to production.

Contact us today to learn more about how we can partner with you to achieve excellence in PCB fabrication and electronic device manufacturing.

For expert guidance on selecting the best PCB fabrication company and optimizing your electronics production, contact Viasion. We are dedicated to delivering quality PCB solutions tailored to your specific needs

Read More: Choosing the Best PCB Fabrication Company: A Comprehensive Guide | Viasion